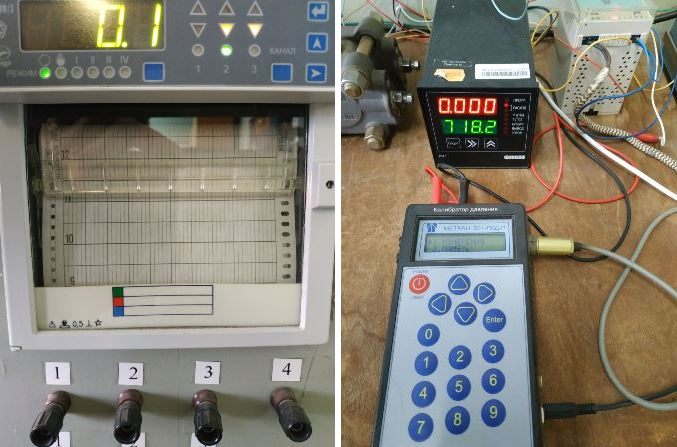

Laboratory of information measuring systems is designed for practical work with hardware and software of modern information measuring systems. The laboratory performs laboratory works on measuring technological parameters and automation of technological processes. The laboratory is used by students and graduate students for research and development of information measuring systems in energy and industry in the process of working on course projects, bachelor’s theses, master’s theses, PhD’s theses.

Information measuring system (IMS) provides technological measurements, mathematical signal processing, data alarm, data archiving, data visualization. Components of the software and hardware complex (SHC) of IMS – programmable logic controllers (PLC), human-machine interface systems (HMI/SCADA), industrial networks (fieldbuses).

Technological measurements are measurements of temperature, pressure, humidity, weight, fuel and electricity consumption, level of liquid and bulk materials, concentrations (composition analysis), rotation frequency, speed, availability and movement, angle of rotation, etc.

Mathematical signal processings are the linearization and filtering of signals, the calculation of key performance indicators. Data alarm is the detection and signaling of technological and emergency events (alarms). Data archiving is the storage of historical data and alarms on external media. Data visualization is a representation of the measured technological parameters on external devices and recorders, on graphic elements of windows of systems of the human-machine interface.

The laboratory consists of: 1) temperature IMS stand; 2) pressure and vacuum IMS stand; 3) IBC stand of energy carriers consumption; 4) level and weight of the medium IMS stand; 5) concentration of gases and liquids IMS stand; 6) remote controlling IMS stand. Laboratory stands are equipped with primary sensors, PLC and HMI/SCADA-systems from the world’s leading manufacturers.

The following topics are studied in laboratory works: technological measurements and devices; metrology; mathematical signal processing; IMS software and hardware; the procedure for calculating the measuring channels of IMS; the procedure of statistical analysis of industrial measurements; schematic diagrams of electrical connections of sensors and transducers to external devices, recorders, I/O modules of industrial PLCs; the procedure of design and IMS functional schemes.