We do not prepare only executors. We offer education for consultants who can understand each stage of the system and can analyze it as a whole. It is difficult to replace such specialists with machines or artificial intelligence, and therefore they will have jobs for years in advance. We teach those who are of great importance for business, science and society:

- programmers of real-time control system

- analysts of technological process,

- system integrators - engineers who are able to make the production process to work through the automation control.

In Ukraine we stood at the beginning of the specialty “Automation and computer-integrated technologies”, took participation in the preparation of professional standards and change as fast as the world requires.

Within the shortest time period our graduates can understand the demands of employers and partners.

Our solutions provide a possibility for industry, buildings and processes to work without human intervention.

Our ideas give partners a competitive advantages to outperform their competitors.

Let's think what will happen if we don't prepare an engineer at an appropriate level.

A big share of our everyday things would not exist without the automation of technological processes. Of course, almost every thing can be done by hand and it will be even cool - it will be unique.

People will always have a job: monotonous, from day to day, from year to year, without prospects and ones development.

Automation has made things accessible to everyone, cheap, with the enough quantity and with any quality. It helps people where they cann’t longer cope with.

Without smart algorithms of turbine control you will not get a stable electricity supply to your sockets, highly skilled plumbers providing stable water pressure in the tap are not widespread, the radiators for space heating are not heated by oneselves.

Access control systems, temperature and pressure control systems for conveyors, elevators, refrigerators, wind turbines, machines, equipment etc. all this has already become an everyday routine.

But every time these routine tasks must be solved in such a way so that it would be profitable and safe. There is no silver bullet for all cases - you need to have imagination, system thinking and knowledge. Moreover, it is necessary to understand the value of imagination and knowledge for the world.

The further the more complicated: the processes are more complex, interconnected and unpredictable. When a store orders a batch of milk on the other end of the production chain the farm starts feed planning for cattle so that the order would be stable for years.

Each link in this chain is a competition for suppliers, customers, markets and professionals. Those, who can provide control over the technological part, transparency and coherence of mechanisms, quick response to events, necessary information for the right people in the right form - will help for their company to find a place in the sun. Companies not engaging such specialists will be out of business.

For various companies – from startups to industrial giants - we provide opportunities to survive and develop. We propose management tools and their application. No current technology company can survive without it.

Our strategy is to group together business, science, education and so that everyone finds oneself benefit. A lot of important things are made for implementation of this goal.

Partnership

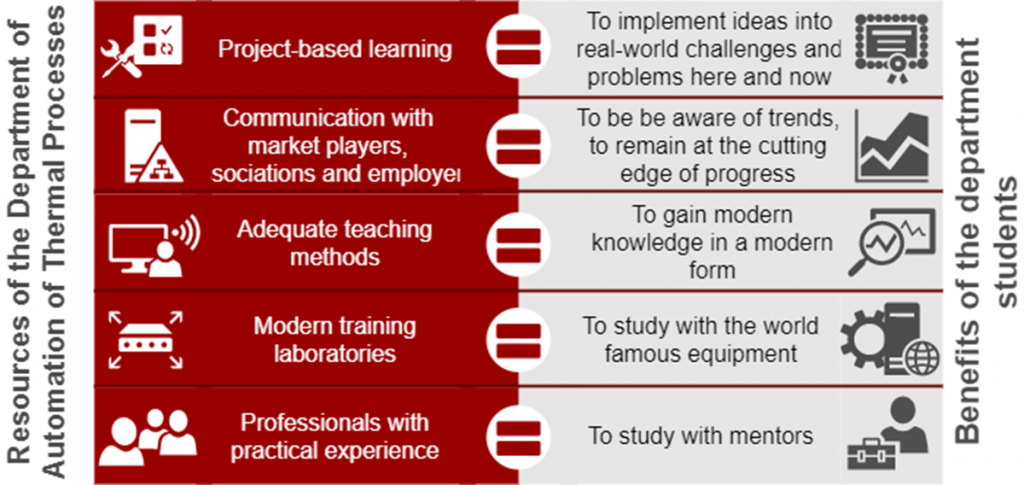

For teaching on a high level, it is important to know what employer companies want. For excellent teaching it is very important to engage companies for curriculum development and to be in trends of innovations.

The Department of Automation of Thermsl Processes is one of the academic founders of the Association of Industrial Automation of Ukraine - APPAU. This association is a real driver of digital transformation of the country's economy. It has gathered under its auspices the best domestic manufacturers, world industry leaders, leading universities, system integrators and industrial companies. Regular events, conferences, projects and meetings provide us a possibility to be informed about the latest world trends, to respond quickly to market demands.

We are members of the international higher education EduNet network which is supported by the German innovative company Phoenix Contact. It provides for us a possibility to exchange experiences, to have access to latest trends in educational technologies and to a wide range of ultra-modern equipment. It is a great opportunity for students to implement their ideas into reality and a perfect motivation for future professionals.

Such world famous and domestic companies as Phoenix Contact, Schneider Electric, Siemens, Raut-Automatic, Klinkmann, Mikrol, Honeywell, Luxsoft have invested in our laboratories. This activity cannot be regarded as a gift. It is investment. We provide knowledge according to current technologies and tips. As a results, companies can receive specialists that are able to cooperate with them. This is a win-win strategy where everyone gets his own benefits.

Projects and Research

The department continually develops different areas of science and engineering which are based on existing resources and achievements and are integrated into Industry 4.0. Such approach provides a holistic view of the today’s technological basis of digital production, including both means of solving existing technological problems and understanding business problems that can be solved by automation control technologies.

The conventional technologies in which we have got significant achievements are automatic control of the technological process parameters. We have got a comprehensive understanding of the methodologies, algorithms and pitfalls of decision implementation and solving new problems. Many of our solutions and algorithms are applied on most Ukrainian thermal power plants. There are achievements within the wide variety of industries - energy, oil and gas, chemical, processing and food industries, manufacturing of building materials and scientific experiments, in housing and communal services and smart homes. We follow pragmatism and experience. The academic and teaching staff provide courses based on their own experience.

We constantly improve ourselves. Advanced Process Control - an ideology without which no building of Smart Factory is approved in developed countries. Tesla has got a very developed advanced production management – and, as a consequence their results are very high. This is the Blue Ocean of the future of industrial automation, and we are involved in this process.

Now we are working on development of an important concept of optimizing technological processes and automation control of heating systems of buildings and cities. The importance of this research has been approved at the highest state level - we have won a grant for such investigations. And maybe next year your bills will decrease because of more efficient distribution of heat. This will be supported with digital twins of equipment and systems, augmented reality software, predictive models, modules of finding optimal control strategy, developed system of recommendations based on machine learning, transparency of information and application of key performance indicators. Decreasing costs and expenses is also one of such indicators.

We follow principles of harmonization with the developed world. The department plays an important role at the state level, promoting the world's best technological practices among domestic business. The aCampus project, implemented together with the German Gesellschaft für Internationale Zusammenarbeit (GIZ) and the national leader of the Fourth Industrial Revolution - APPAU, aims to increase the level of knowledge of progressive Ukrainian companies within the concept Industry 4.0. We have translated, adapted and approved at the level of state standard the most important ideas underlying the success of global companies - unambiguity, clarity and usefulness of Key Performance Indicators. This is a set of measurements of the efficiency of production processes that evaluate the development strategy of any technological enterprise. This is "Lean production" and constant change for the better to achieve maximum efficiency. We have published a lot of educational materials, organized many meetings and conferences for promotion of the implementation of ideas of KPI, cybersecurity, production management and interaction of separate systems.

Technical support

We have formed, constantly update and develop laboratory complexes that cover all automation tasks: equipment selection, automated computer design, metrology, local systems programming, web-programming of accompanying services, programming and design of supervisory tasks, information networks, industrial reliable communication, embedded systems and Industrial Internet of Things, augmented reality technologies.

We implement into the educational process international standards using equipment of world famous companies, so that our graduates can compete even outside the country.

These laboratories are a joint achievement of the department staff, former sponsors and companies that are ready to invest in preparation of high quality specialists. Moreover all this equipment is available to students for implementation of their own projects and ideas. This is a unique opportunity to gain experience and skills with your own hands and you should receive benefit from it.